Maintenance Management that’s

Easy to use. Powerful. Mobile.

Equipment

Single screen identifies and describes each equipment, its components, spare parts, maintenance history and related documents. The equipment screen is a focal point in the system for most users.

aa

Work Orders

Describes, schedules and tracks planned maintenance activity. Tasks, parts lists and related documents are included for each job. Work orders are automatically closed when work is completed.

aa

Preventive Maintenance

Describes and schedules jobs for periodic maintenance and inspections. Each PM contains a task list, parts list and links to related documents. PMs are automatically rescheduled when closed.

Maintenance

History

Stores all your Maintenance History for each equipment showing all planned and unplanned jobs. Equipment reports present: dates & job description, parts used & cost, cause codes, user & technicians comments, labor time & cost.

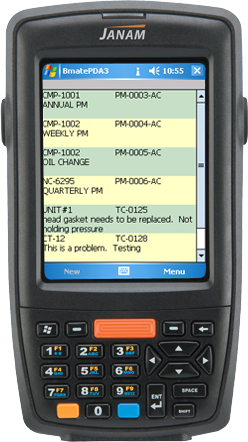

PDA Module – Benchmate Power in the Palm of Your Hands!

The PDA Module for Benchmate captures maintenance activity and equipment condition for Scheduled Jobs, as well as, ‘on the floor’ maintenance, as it occurs. Benchmate PDA Module ensures accuracy, timeliness and completeness. Jobs assigned to a technician are downloaded to the Personal Digital Assistant (PDA) and displayed as a list of jobs. Activity for unplanned jobs and emergency requests can also be recorded.

Making a Case for Better Maintenance.

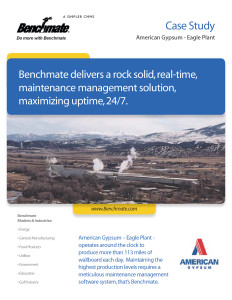

American Gypsum Eagle Plant

Benchmate delivers a rock solid, real-time, maintenance management solution, maximizing uptime, 24/7.

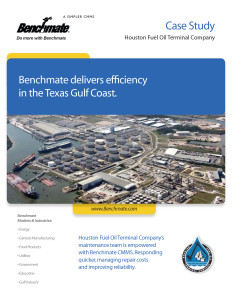

Houston Fuel Oil Terminal Company

Benchmate delivers efficiency in the Texas Gulf Coast.

Southern States Cooperative

Reaping benefits from planting Benchmate’s PDA Module, nation wide.

Look Who’s Talking About Benchmate

“We researched several other CMMS programs and, we purchased Benchmate. It was by far the easiest program to use, and that was the biggest factor in our purchase decision.”

“We’ve boosted productivity by performing more focused PM’s, and elminating the small breakdowns that happen throughout the day. With the PDA Module, our maintenance team manages our business head-on, versus fighting problems as they present themselves.”

“We needed a better way to manage the data related to equipment PM’s, repairs and scheduled maintenance. Benchmate was chosen for its simplicity & intuitive interface. Maintenance and production rely on it to

Keep production equipment running as much as possible, Minimal downtime is key.”

“After researching several solutions, and realizing Benchmate’s ease-of-use, diversity, scalability and cost would empower our team quickly and expand to support our global facilities. Benchmate provides labor & workflow efficiencies throughout our company, real-time.”